Boosting Engine Performance The Critical Role of Unseen Parts

When evaluating a vehicle’s capabilities, most enthusiasts focus on horsepower figures, torque curves, or the latest electronic driving aids. Yet beneath these headline-grabbing features lies an intricate ecosystem of components that truly determine how an engine performs. Boosting engine performance: The critical role of unseen parts isn’t just a concept—it’s the hidden reality of automotive engineering that separates reliable, high-performing engines from those that fail to deliver their promised potential.

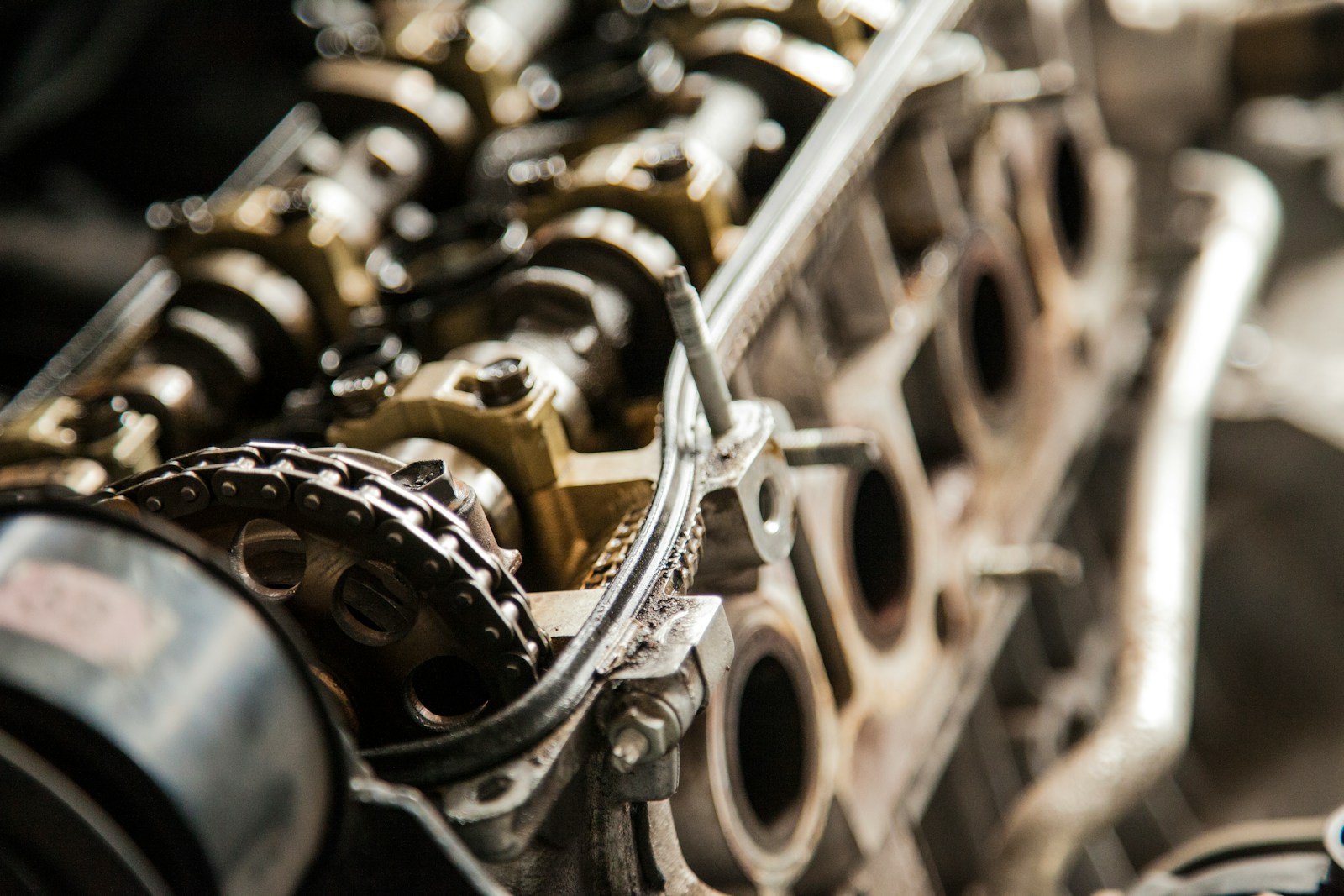

The invisible heroes of engine efficiency

The performance of your vehicle depends heavily on components you’ll likely never see during routine maintenance. These unsung heroes work tirelessly in harsh conditions, ensuring your engine operates at peak efficiency while protecting it from the extreme pressures and temperatures generated during combustion cycles.

Consider the humble ba r in your engine’s valve assembly. This small, precisely engineered component controls the critical timing of valve operations, directly influencing combustion efficiency, emissions output, and power delivery. A quality ba r ensures valves open and close at exactly the right millisecond, while substandard versions can lead to power loss, increased fuel consumption, or even catastrophic engine failure. Yet how many vehicle owners could identify this component or understand its significance to their driving experience?

Similarly, heat exchanger gaskets play a fundamental role in maintaining optimal engine operating temperatures. These seemingly simple seals create the critical barriers between different fluid systems, preventing coolant leakage while withstanding extreme thermal cycling. When these gaskets fail, the consequences range from poor fuel economy to complete engine seizure due to overheating.

Temperature management: The foundation of performance

Engine performance isn’t just about what happens in the combustion chamber. The management of heat throughout the engine system fundamentally determines both power output and longevity. This is where heat exchanger gaskets become critical performance components rather than mere maintenance items.

Modern engines operate at increasingly higher temperatures to maximize efficiency and reduce emissions. A high-quality heat exchanger gasket maintains perfect seals under these extreme conditions, ensuring cooling systems operate at designed specifications. Even a minor gasket degradation can allow microscopic coolant leaks that gradually reduce cooling efficiency, leading to higher operating temperatures that compromise performance long before triggering warning lights.

The materials science behind these gaskets represents decades of engineering advancement. From composite fiber technology to specialized silicon compounds, manufacturers invest heavily in developing materials that can withstand not just heat but also the chemical effects of modern coolants and oils. When upgrading your vehicle’s performance, have you considered whether your cooling system components can handle the additional thermal stress?

Precision components and their impact on power

The relationship between precision-manufactured components and engine output becomes clear when examining the ba r system that controls valve timing. These components operate within tolerances measured in microns, with even minor variations dramatically affecting air-fuel mixture delivery and exhaust gas evacuation.

You might wonder why some engines of identical displacement produce significantly different power figures. Often, the answer lies not in major components but in the precision of these small, unseen parts. Performance-oriented ba r assemblies can allow engines to breathe more efficiently at higher RPMs, unlocking horsepower that would otherwise remain inaccessible.

What makes this aspect of Boosting engine performance: The critical role of unseen parts particularly relevant is that these components often represent cost-effective improvements compared to major modifications. A performance-grade ba r system might deliver noticeable power gains at a fraction of the cost of exhaust system modifications or electronic tuning.

The performance chain: Why every component matters

Engine performance represents a chain of interconnected systems, each only as strong as its weakest link. This explains why throwing expensive parts at an engine sometimes yields disappointing results—the performance chain remains limited by overlooked components.

For instance, installing high-flow fuel injectors without addressing the thermal management capabilities of your heat exchanger gaskets might initially increase power output. However, the additional heat generated could eventually compromise performance as the cooling system struggles to maintain optimal operating temperatures. This highlights why comprehensive understanding of engine systems matters when Boosting engine performance: The critical role of unseen parts.

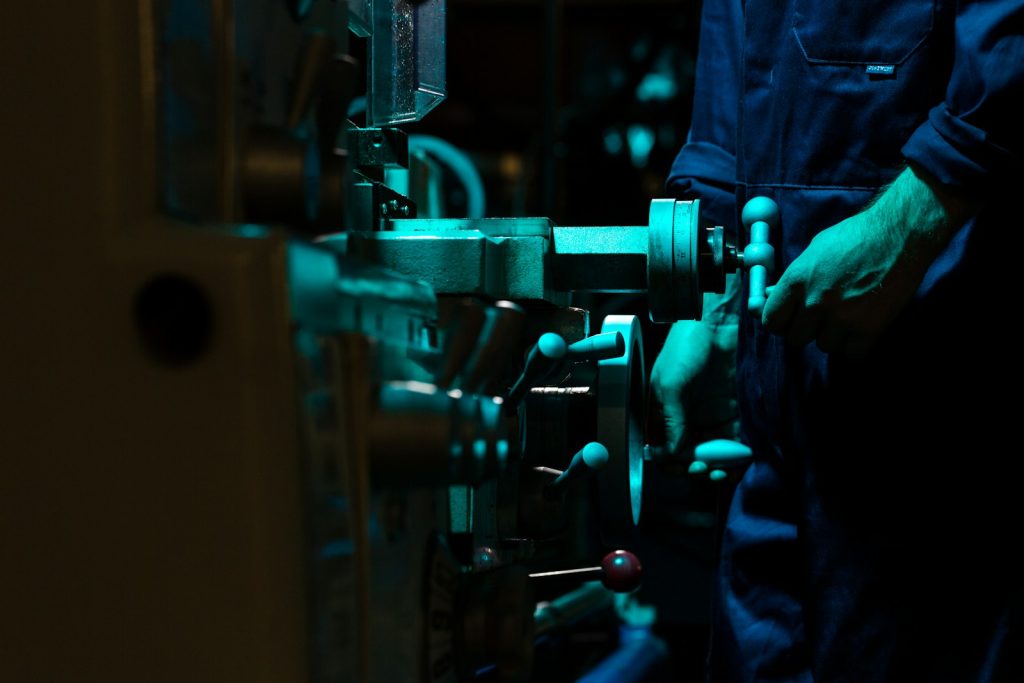

Maintenance versus upgrading: Making informed decisions

Should you simply maintain your engine’s unseen components, or should you consider upgrading them as part of a performance enhancement strategy? The answer depends on your specific goals and the condition of your current engine.

For vehicles operated primarily under standard conditions, quality replacement parts that meet manufacturer specifications typically provide the best value. However, for engines subjected to more demanding use—whether through performance modifications, towing applications, or extreme climate conditions—investing in upgraded components often delivers meaningful benefits.

Heat exchanger gaskets engineered with advanced materials can maintain proper sealing under conditions that would cause standard gaskets to fail. Similarly, performance-oriented ba r components can improve valve train stability at higher-than-stock RPMs, protecting your engine while delivering improved power characteristics.

When evaluating potential upgrades, consider the entire performance ecosystem rather than isolated components. Will your cooling system support increased power output? Can your oiling system maintain pressure under more demanding conditions? These questions highlight the integrated nature of engine performance enhancements.

Finding the right balance for your needs

Ultimately, Boosting engine performance: The critical role of unseen parts requires balancing multiple factors including reliability, performance objectives, and budget considerations. The most successful approach typically involves understanding your engine’s specific limitations and addressing them systematically rather than simply installing the most expensive components available.

By recognizing the critical importance of components like quality heat exchanger gaskets and precision ba r assemblies, you can make informed decisions that truly enhance your engine’s capabilities without compromising its longevity. Remember that genuine performance improvements come not just from headline modifications but from ensuring every component in the performance chain can operate at its optimum level.

Your engine deserves attention to these often-overlooked details—because true performance isn’t just about what’s visible, but about the harmonious operation of every component working together under the most demanding conditions.