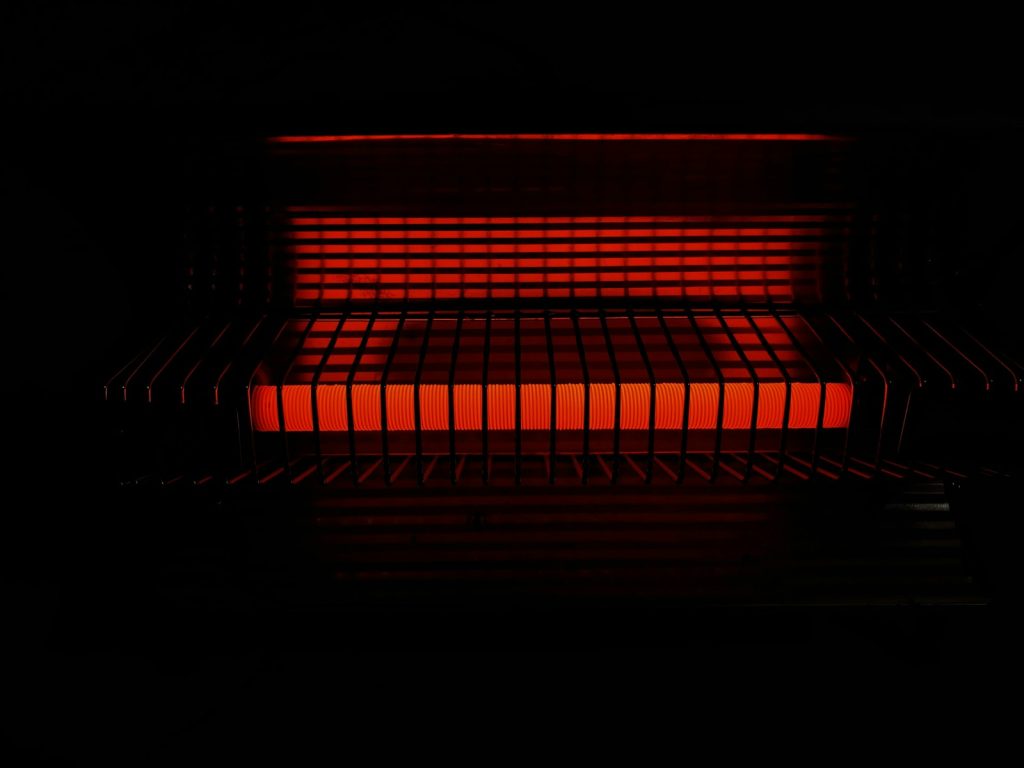

Crafting Enduring Connections in High-Temperature Environments

In industrial settings where extreme temperatures are the norm, crafting enduring connections in high-temperature environments becomes not just a technical challenge but a critical safety and operational imperative. With over three decades of experience in thermal sealing solutions, our engineering team has witnessed firsthand how proper connection integrity directly impacts plant efficiency, maintenance schedules, and ultimately, the bottom line. The demanding nature of high-temperature applications requires specialized knowledge of materials, proper installation techniques, and understanding of thermal expansion dynamics—elements that separate adequate connections from truly enduring ones.

The critical role of material selection

When temperatures climb beyond normal operating ranges, standard connection materials begin to fail. This is where specialized knowledge becomes invaluable. Heat exchanger gaskets represent one of the most critical components in high-temperature systems, serving as the primary defense against leakage where pipes, vessels, and equipment connect. The selection process for these components must account for not just the maximum temperature, but also pressure ratings, chemical compatibility, and expected thermal cycling patterns.

Graphite gasket sheet material has emerged as an industry standard for applications reaching temperatures up to 950°F (510°C) in oxidizing environments, and even higher in non-oxidizing conditions. The popularity of graphite stems from its remarkable thermal stability, chemical resistance, and ability to maintain seal integrity despite repeated thermal cycling. What many maintenance engineers don’t realize is that graphite’s performance characteristics can vary dramatically based on purity levels, density, and manufacturing processes. Premium graphite gasket materials contain over 98% carbon content with minimal binders, resulting in superior heat resistance and significantly extended service life.

You might wonder: “Why does material selection matter so much for my specific application?” The answer lies in the physics of thermal expansion and the chemistry of material degradation. Inferior materials may seem cost-effective initially but lead to frequent replacement cycles, unexpected shutdowns, and potentially catastrophic failures that no facility can afford.

Engineering considerations for thermal cycling

Crafting enduring connections in high-temperature environments requires thinking beyond static conditions. In reality, most industrial systems undergo thermal cycling—periods of heating and cooling that put tremendous stress on connection points. Each cycle causes microscopic movements as materials expand and contract at different rates. Over time, these movements can lead to connection loosening, gasket compression set, and eventual leak paths.

The design of flanged connections, particularly in heat exchangers, must account for this reality. Engineers must calculate not just the operating temperature but the full range of expected thermal cycles. Proper bolt loading becomes particularly critical, as insufficient loading leads to immediate leaks while excessive loading crushes gasket materials and reduces their recovery properties. Advanced finite element analysis now allows engineers to model these complex interactions, predicting potential failure points before they occur in real-world applications.

Flange design, bolt material selection, and torque specifications all play interconnected roles in creating truly durable connections. For example, when using graphite gasket sheet material, the specified compression typically ranges between 5,000 and 10,000 psi depending on the specific grade and application. This precise compression range maximizes both sealing effectiveness and gasket longevity through thermal cycles.

Flange design, bolt material selection, and torque specifications all play interconnected roles in creating truly durable connections. For example, when using graphite gasket sheet material, the specified compression typically ranges between 5,000 and 10,000 psi depending on the specific grade and application. This precise compression range maximizes both sealing effectiveness and gasket longevity through thermal cycles.

The unique challenges of extreme temperatures

Beyond the more common high-temperature applications lies the realm of extreme temperature sealing—environments exceeding 1,500°F (815°C) where conventional wisdom about connections no longer applies. In these demanding scenarios, mica gasket material often becomes the solution of choice. Derived from natural silicate minerals, mica offers exceptional thermal stability with decomposition temperatures exceeding 1,800°F (982°C) in some formulations.

What makes mica particularly valuable in extreme applications is its unique layered structure that maintains compressibility even after extended exposure to high temperatures. Unlike many other gasket materials that become brittle and lose recovery properties, properly formulated mica gasket material maintains essential elastic properties. This characteristic proves invaluable in applications like industrial furnaces, gas turbines, and exhaust systems where maintaining seal integrity directly impacts both efficiency and emissions compliance.

The implementation of mica-based sealing solutions requires specialized knowledge. The material exhibits different compression characteristics compared to graphite gasket sheet products, necessitating modifications to installation procedures. Flange surface conditions become even more critical, with surface roughness specifications typically tighter than those for softer gasket materials. Proper installation technique can easily double the effective service life of these specialized connections.

Installation best practices for longevity

When crafting enduring connections in high-temperature environments, proper installation technique often determines success or failure more than any other factor. The most carefully selected heat exchanger gaskets will fail prematurely if installation procedures don’t follow established best practices. Our field engineers have documented cases where identical gasket materials in identical applications achieved drastically different service lives based solely on installation quality.

Flange alignment represents the foundation of proper installation. Misalignment creates uneven compression across the gasket face, leading to localized stress concentrations that become failure initiation points. Modern laser alignment tools now make precise flange positioning possible even in tight spaces and complex piping configurations. The investment in proper alignment equipment typically pays for itself within the first maintenance cycle through extended gasket life.

Bolt tightening sequence and torque values follow in importance. The crosshatching pattern familiar to experienced maintenance personnel ensures even gasket compression and prevents flange distortion. However, what many overlook is the importance of incremental torquing—applying torque in stages rather than attempting to reach final values in a single pass. This gradual approach allows gasket materials to flow and adjust properly, particularly important with graphite gasket sheet products that exhibit some degree of cold flow under compression.

Monitoring and predictive maintenance

The evolution of industrial sensing technology has transformed how we approach connection integrity in high-temperature systems. Modern facilities now implement comprehensive monitoring programs that detect potential connection failures before they occur. Ultrasonic emission detection, infrared thermography, and even specialized gasket sensors with embedded monitoring capabilities provide real-time data on connection health.

These technologies allow maintenance teams to transition from reactive to predictive maintenance models. Rather than waiting for visible leakage or catastrophic failure, subtle changes in connection characteristics can trigger planned interventions. This approach not only prevents unexpected downtime but also extends the effective service life of specialized components like mica gasket material and premium heat exchanger gaskets by addressing minor issues before they escalate.

The data gathered through these monitoring systems becomes invaluable for continuous improvement efforts. Patterns of wear, thermal cycling effects, and material performance under actual operating conditions inform future design decisions. This feedback loop allows for ongoing refinement of connection specifications, material selections, and maintenance protocols.

Crafting enduring connections in high-temperature environments represents both science and art—blending materials knowledge, engineering precision, and practical field experience. As industrial processes continue pushing temperature boundaries, the value of specialized connection expertise only grows. The most successful facilities recognize that the modest additional investment in premium sealing materials and proper installation practices yields exponential returns through extended service life, reduced maintenance costs, and enhanced operational reliability.